While no two supply chains are ever the same, most leadership teams have found they are trying to accomplish one common goal: to bring together numbers complex systems and relationships into usable information that improves their customer experience.

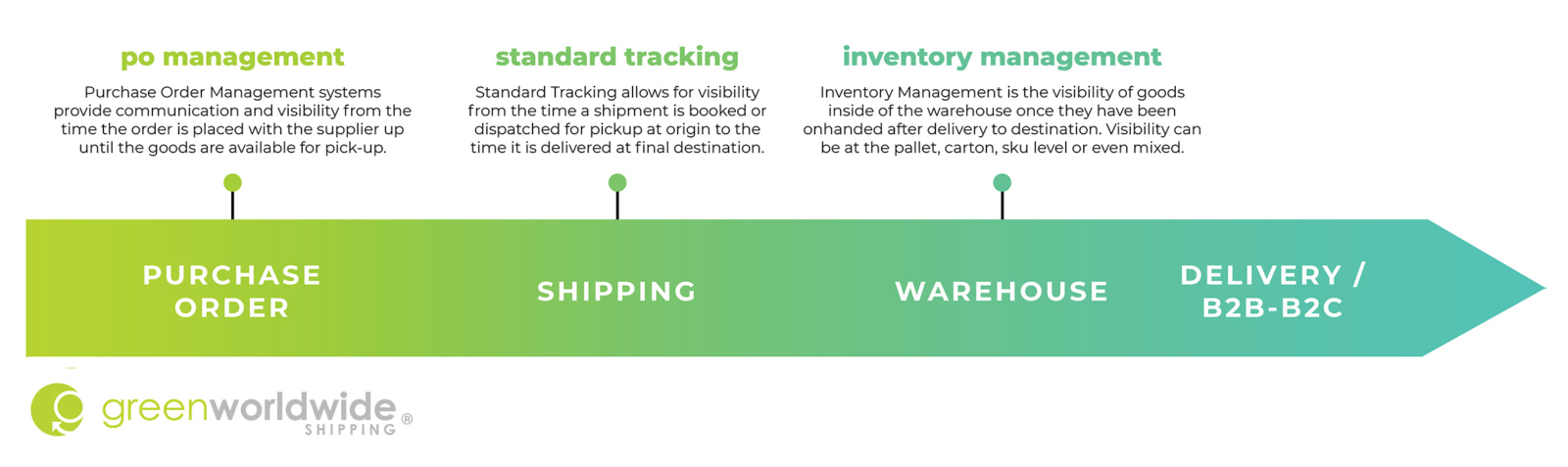

A standard supply chain begins with production, which for most is done through a purchase order, and ends by delivering the goods to the customer who can either be a business (B2B) or retail consumer (B2C). What differentiates good companies from great ones is how efficient their supply chains are.

Let’s take a look at the path data must travel along a typical supply chain and what it takes to get from purchase order to delivery.

There are three different management and tracking systems within a supply chain to provide the information needed to shippers: PO Management, Standard Tracking and Inventory Management.

A good supply chain will involve all three systems. But inevitably issues can, and often do, arise when three different data applications don’t communicate with each other. Coupled with human error, clean data that can be used for analytical management is often difficult to achieve without a dedicated effort.

The redundancy of multiple systems can lead to:

- Lack of compliance

- Zero transparency

- No accountability

PATH TO INTEGRATION

What great companies can do is automate all three applications into a single supply chain function which provides a centralized source for connected data and visibility. This allows businesses to ensure that the data being captured is accurate and consistent, instead of relying on fragmented information from disconnected teams.

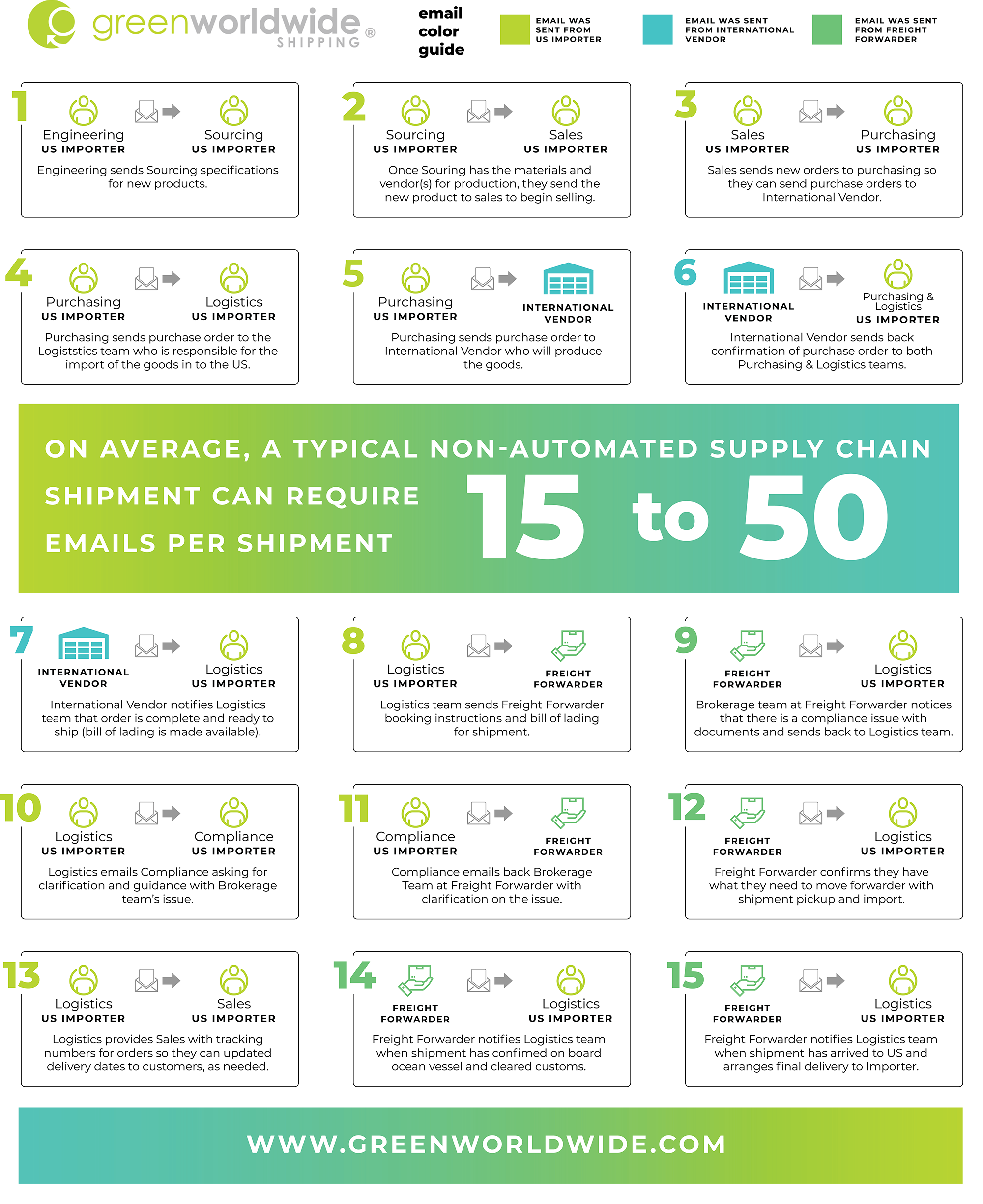

For example, let’s take a look at the typical amount of communication and information that is transferred between parties in a standard supply chain.

In total, over 15 emails can be needed to complete even for a basic, single shipment. The more complex or time-sensitive a shipment is, the more coordination is needed to move it throughout the supply chain. Taking into account the number of annual shipments a company moves; the number of managerial factors and communication overhead can exponentially increase to overwhelming levels.

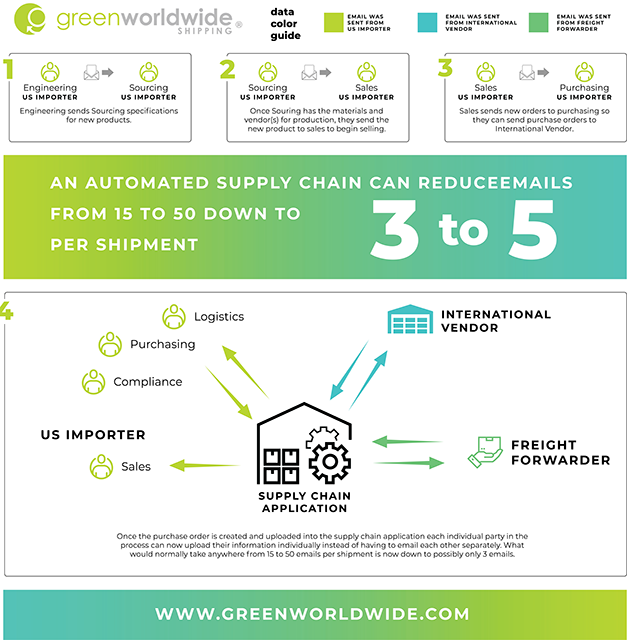

Now, if we look at how this same supply chain might look through the lens of automation, things start to look much more manageable.

Prior to the purchase order being created, there will still need to be some emails between Engineering, Sourcing, Sales and the Purchasing departments. But once the order has been created, it can be uploaded into the supply chain automation application at which point each party in the shipment process can upload their required information. Each party can perform their functions in a centralized platform and hold each other accountable. This reduces the chance of miscommunication and redundancy between teams.

Prior to the purchase order being created, there will still need to be some emails between Engineering, Sourcing, Sales and the Purchasing departments. But once the order has been created, it can be uploaded into the supply chain automation application at which point each party in the shipment process can upload their required information. Each party can perform their functions in a centralized platform and hold each other accountable. This reduces the chance of miscommunication and redundancy between teams.

Restrictions can be added to different parties in the process such as the Sales team. They can be permitted to view the status of a shipment but not have the authorization to make decisions on it. This allows them to notify customers, if needed, on where their orders are in the production process, but can restrict different parties from approving rush orders with International Vendors.

Ultimately, supply chain automation allows a company to see processes and have communication that they otherwise would not have had prior to its availability.

CLEAN DATA BENEFITS

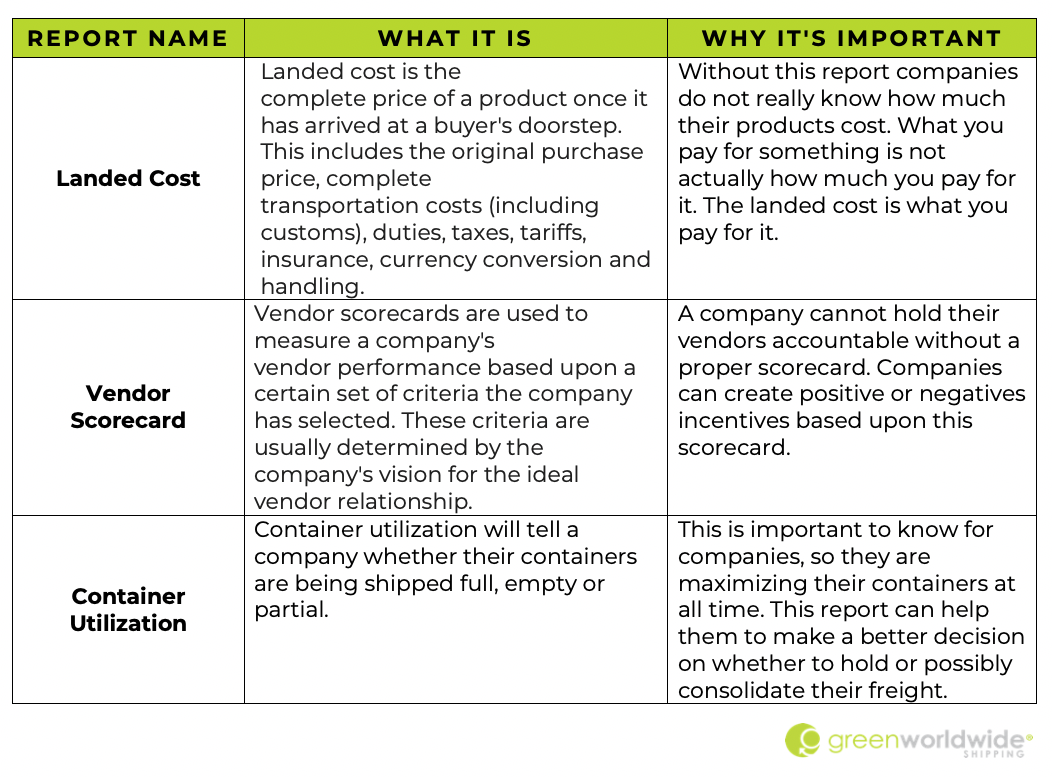

By connecting multiple systems and reconciling the information that feeds back and forth, a supply chain management tool is able to provide clean data to feed integrated reporting, scorecards, and decision-making dashboards.

Some of the most popular management reporting includes:

ARE YOU LEVERAGING TECHNOLOGY IN YOUR SUPPLY CHAIN?

If the answer is yes, but you are still dealing with Excel-based reporting, there is optimization being left on the table. Green Engineered Management (GEM) powered by Green Worldwide Shipping is a powerful platform that creates supply chain transparency that makes your data work for you.

Stay up-to-date on freight news by following us on Facebook, Twitter, and LinkedIn. For continuous updates, make sure to check out our website at greenworldwide.com.